StabilRoad® is stable and durable! S

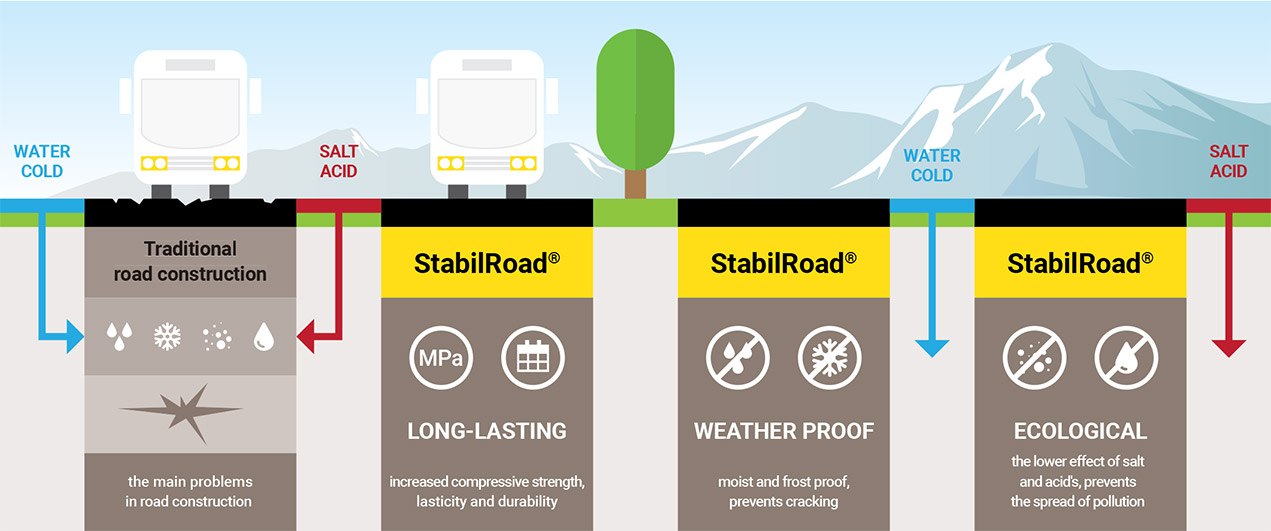

Modern civil engineering has used cement as the main stabilizer due to its excellent bonding properties. But it does not work on clay, sandy, muddy soil. In this case, besides better bonding, fill surfaces should be used. Only problem is cement-treated soils become very rigid and the risk of cracking is very high. By using the StabilRoad® cement additive in a corresponding amount with the amount of cement, there is a no significant risk of cracking. This is due to its ability to change the parameters of the concrete’s bending strength. StabilRoad® is today one of the most advanced and technologically most innovative soil stabilization material and technology in the world. StabilRoad® is a whitish powder made of 100% natural minerals with no synthetic chemicals. StabilRoad® technology has been developed in Germany and has been used for nearly 20 years in nearly all of the world’s climate zones.

Technological specifications

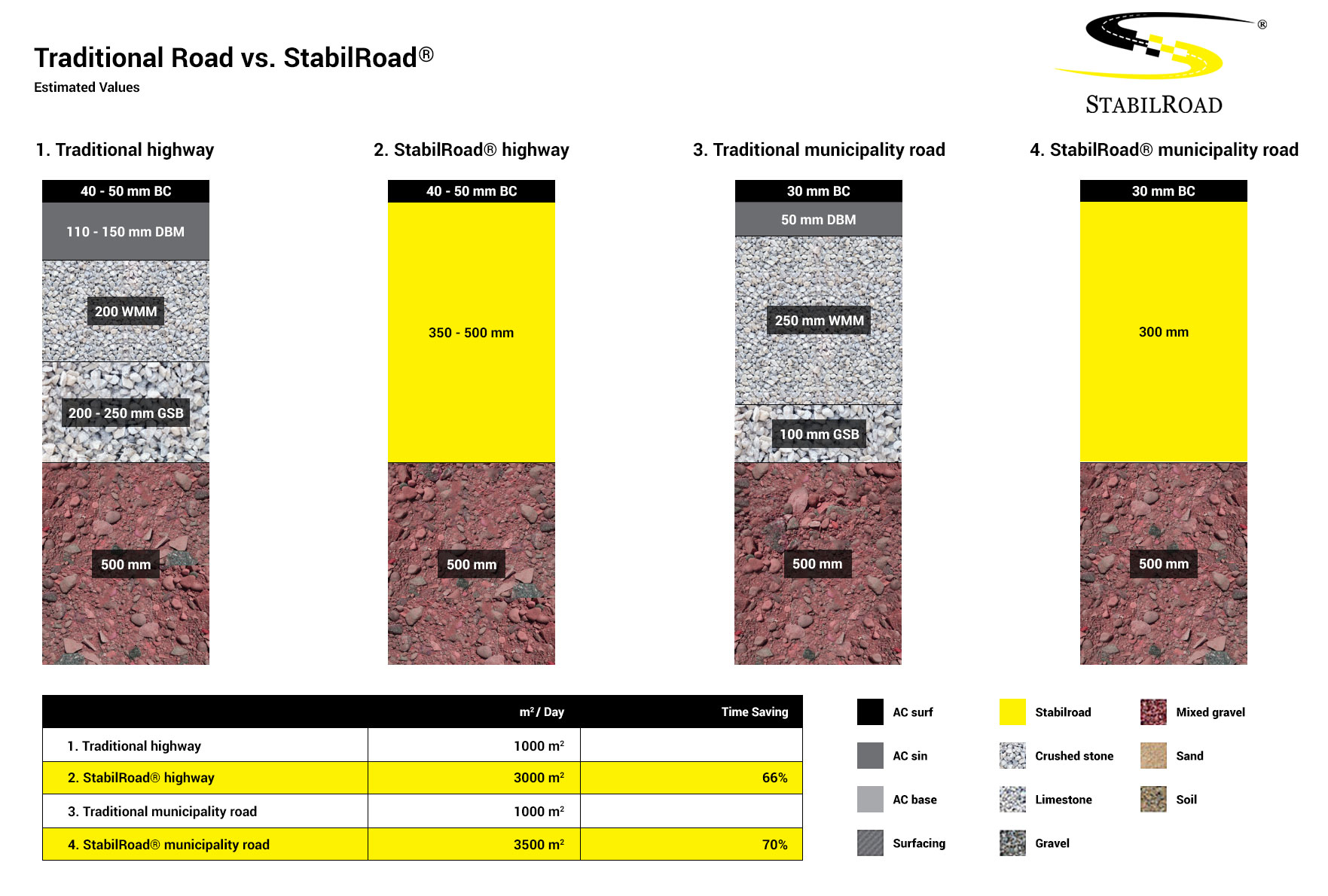

The most important feature of this technology is that by using the StabilRoad® additive and special technology we can significantly accelerate the construction process, reduce the cost of work, and at the same time achieve a very strong, elastic, waterproof and frost-proof surface. All this can be achieved by reusing local soil.

The biggest advantage of using such a stabilization method is that there is no need for the excavation of old or existing soil, the disposal and the return of the new ground. Some hours after the necessary work is completed can be done, the treated surface can be put into operation. Stabilizing with StabilRoad® technology entails the mixing together of existing soil (including old asphalt), StabilRoad® and cement (Portland cement needed, clinker content> 95%) is mixed together.

The StabilRoad® additive increases the process of cement hydration, in which cement particles form a reactive water by reacting new bonded compounds, which consists of a concrete skeleton. As a result of crystallisation, water-insoluble compounds are formed which make the treated layer non-water-absorbing. Increasing the cement hydration will reduce the amount of cracks caused by volume reduction, increasing the elasticity of the stabilized surface, compression and tensile strength, and the material becomes cold and waterproof.

The stabilized surface can be compared with concrete in its properties. Stabilizing with StabilRoad® is used instead of substrata and frost protection layers. By using StabilRoad®, each treated layer can also work as the top layer of the coating on low-traffic roads. Depending on the field of application, a protective layer of asphalt may be necessary as a final layer, for example by coating or asphalting.

StabilRoad® technology was first used in India in August, 2017 by M/S Krishnapatnam Port Company Limited. StabilRoad® India have done close to 6 kilometers in krishnapatnam port and close to 5 kilometers in the city of Hyderabad, close to 3 kilometers in Vijayawada in Andhra Pradesh and 6 Kilometers in Kerala with excellent results. Presently, we are also in the process of constructing roads in Andhra Pradesh, Kerala, Maharashtra and Punjab using this technology.

Consists of only 6 stages

Is scientifically proven

Meets the required conditions

Saves time and costs

Gives ecological preference

StabilRoad® is a modern and innovative soil stabilizing technology. The existing soils are processed with cement and special additive. This makes the soil very resistance to the compressive strength as well as elastic, waterproof and frost resistant.

High quality

The quality and warranty of StabilRoad® with over 20 years of experience on several continents, different climate zones and numerous soils of different types helps in great quality of construction of roads.

Economical

Stabilizing is carried out on the layers of the existing soils, by mixing it with cement and StabilRoad® additive. On the contrary to the common road construction technology there is no need to dig out existing soil. We can utilise the existing soil or asphalt. We need not bring in new soils or aggregates to construct roads.

StabilRoad® technology is scientifically proven!

StabilRoad® technology has been developed in Germany

StabilRoad® is manufactured by a German manufacturer specializing in the stabilization of soil using StabilRoad® technology. The manufacturer has contributed a lot to laboratory studies to create a stabilizing supplement suitable for use in very different climatic conditions and for different soils. StabilRoad® material is produced by a manufacturer based in Germany. The StabilRoad® treated layer can also work well on top of the coating on low-traffic roads. The new base and freezing layer are made from the existing pavement and the base material is stabilized with StabilRoad® additive and cement, by strengthening the existing material with cement and StabilRoad The biggest advantage of this stabilization method is that there is no need to remove the existing soil but it can be mixed with cement and StabilRoad® additive.

StabilRoad® is manufactured by a German manufacturer specializing in the stabilization of soil using StabilRoad® technology. The manufacturer has contributed a lot to laboratory studies to create a stabilizing supplement suitable for use in very different climatic conditions and for different soils. StabilRoad® material is produced by a manufacturer based in Germany. The StabilRoad® treated layer can also work well on top of the coating on low-traffic roads. The new base and freezing layer are made from the existing pavement and the base material is stabilized with StabilRoad® additive and cement, by strengthening the existing material with cement and StabilRoad The biggest advantage of this stabilization method is that there is no need to remove the existing soil but it can be mixed with cement and StabilRoad® additive.

Lab Reports

CSIR Indian Institute of Toxicology Research - Lucknow

Hyderabad Road - ECIL

Hyderabad Road - NTR Marg

Krishnapatnam Port - Andhra Pradesh

Vijayawada - Andhra Pradesh

Completion Certificate

Hyderabad GHMC NTR Marg

Hyderabad Road GHMC ECIL

Krishnapatnam Port

Where to use StabilRoad®

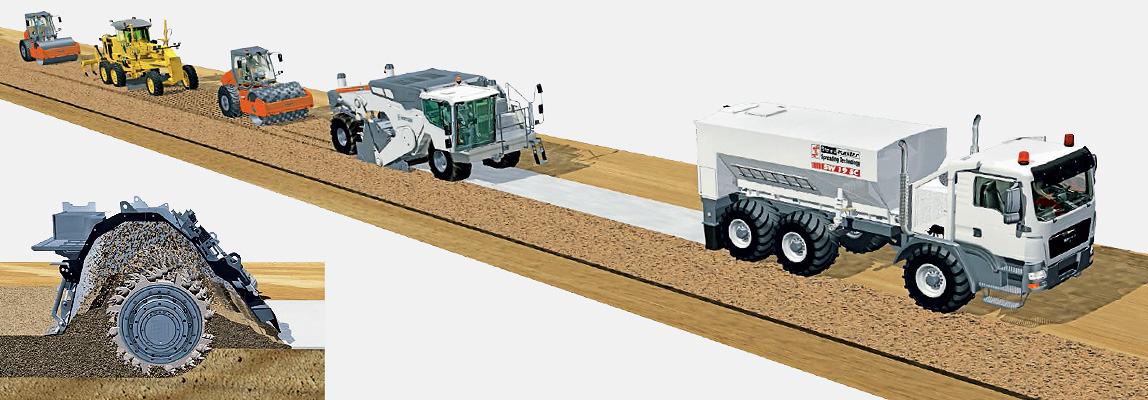

StabilRoad® process consists of 6 steps

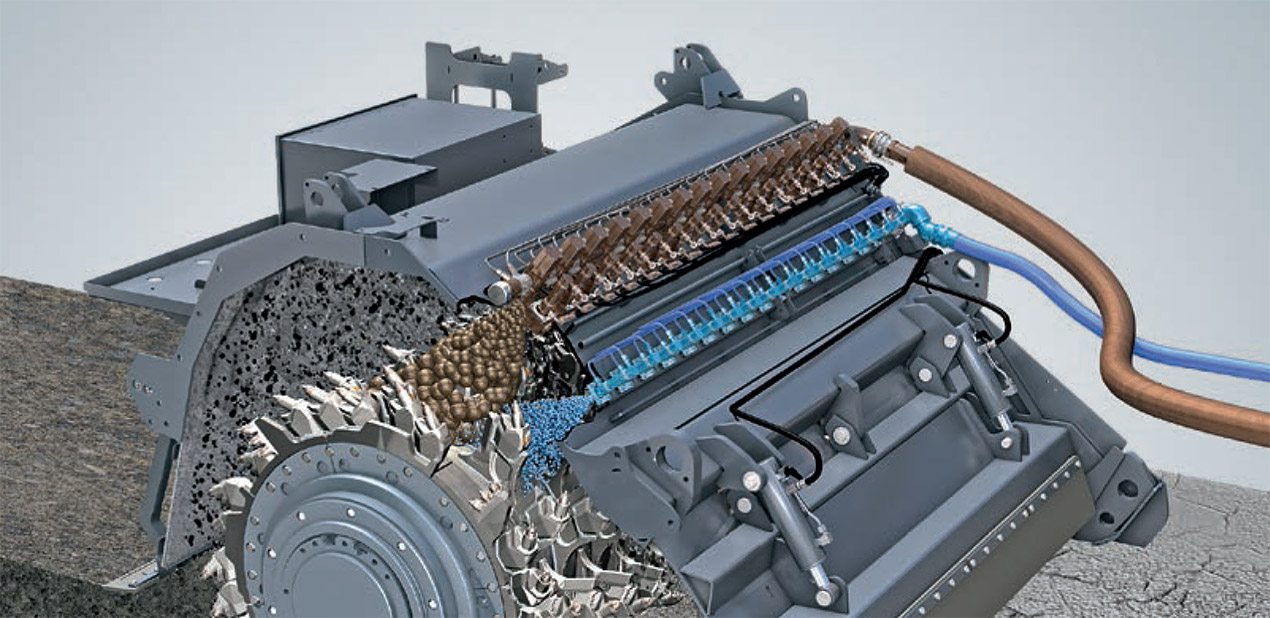

- We perform soil laboratory tests, we explain the precise composition of the soil, the amount of cement needed and the amount of StabilRoad® additive.

- On existing soil, cement and StabilRoad® additive are applied.

- The soil stabilizer mixes the entire soil with cement and StabilRoad® and adds the required amount of water during mixing.

- The cross-linked soil is compressed by the rolling method and the top layer is levelled and smoothed with a grader.

- Final compression is completed.

- Depending on the weather conditions the stabilized surface is sprayed with water, to ensure the required humidity in the hardening process

During the operation of stabilized soil, quality control is performed and the results of laboratory measurements are presented

NB! The precision of the German manufacturer’s technology is closely monitored. All work is subject to technical supervision. Stabilizing the soilwith StabilRoad® technology helps to increase the strength of the existing soil, make it moisture-proof and frost-resistant. It is suitable for stabilizingall types of soils (including clay, old asphalt, etc.). Depending on the soil screen curve, it may be necessary to add fines in some cases.

StabilRoad® advantages

- High quality control of the product by German specialists.

- The product is made of natural materials.

- Accelerates the cement hydration process.

- Improves stabilized soil cover properties.

- Homogeneous composition of the product, which allows to control the chemical reaction.

- Extremely high compressive strength and coherence of compounds.

- Eliminates the development of expansion fractures.

StabilRoad® Facts

StabilRoad® provides a stable substrate

Do you plan to build a new road, improve existing roads, build a car park or a warehouse?

- Do you want to do it again and again, year by year, filling and filling and levelling surfaces?

- Do you want the road to be solid – not to break, crack or freeze?

- Are you ready to stabilize the soil so that it lasts for decades?

- If so, StabilRoad® is your right choice!

Today StabilRoad® is one of the most advanced and technologically most innovative materials and technologies in the world. StabilRoad® technology has been developed in Germany and has been used for nearly 20 years in most of the world’s climate zones. StabilRoad® technology is used in Europe, Scandinavia, Russia, India, the USA and many other countries. The most important feature of using the StabilRoad® additive and special technology is that we can significantly accelerate the construction process by reducing the cost of work, at the same time achieving a stable, durable and long-lasting surface. Some hours after the necessary work has been done, the treated surface is ready to be used. Depending on the field of application, a protective layer of coating or asphalting may be necessary.

StabilRoad® technology is scientifically proven

StabilRoad® is a cement additive which chemical effect is to increase the cement hydration processes. Cement hydration is a chemical process in which cement particles by reacting with water form new related compounds, which make up a concrete skeleton. As a result of crystallization, water-insoluble compounds are formed, making the treated layer non-water-absorbing. By increasing the cement hydration the amount of cracks caused by volume reduction decrease. At the same time the elasticity, compression and tensile strength of the stabilized layer increases and becomes cold-and moisture-resistant. In its properties the stabilized layer can be compared with concrete. The stabilized material has a compressive strength of 3-15N / mm2. It also has a very high load capacity, which is evenly distributed on a very large surface. This is sufficient for all objects described in this brochure.

StabilRoad® technology allows you to achieve a much higher quality and longer lasting stabilized base than achieved by classic stabilization. The technology has been developed by taking into account a large variety of climatic conditions, soils, norms and requirements, and therefore almost all soil types can be stabilized. StabilRoad® technology can be applied to all road categories. The StabilRoad® product can also be used as a modifying additive in construction concrete and cement mixtures to improve their protective properties, accelerate the process of hardening, increase durability and compression strength, while maintaining high elasticity.

StabilRoad® Ecology and Environment

StabilRoad® meets all the necessary requirements

Parallel studies on the chemical composition and mechanical properties of StabilRoad® technology have been carried out In Estonia and that technology meets all the international standards and safety requirements. In co-operation with Estonian Road Administration and the company Skepast & Puhkim OÜ, the pilot project for scientific research “Testing of materials for stabilizing gravel” was carried out in 2015-2016. The use of the StabilRoad® additive in Estonian conditions and the cost-effectiveness of technology was observed in the Master’s Thesis “Innovative Technologies for Stabilizing Soils in Road Construction” in 2016. It has been proven that StabilRoad® technology helps to achieve a concrete-solid, elastic, crackle-free, frost-proof and long lasting surface. StabilRoad® technology has become an innovative alternative to our conservative, old-fashion road building technologies.

Studies have been done on StabilRoad® product by Council of Scientist & Research Institutes like Central Road Research Institute, Indian Institute of Toxicology Research & National Institute of Technology Warangal in the fields of Durability, Strengths, Water absorption and Environmental impact studies in the filed of leaching into Water and soils. Environmental studies proved to be safe with the product. All the studies done in various fields have yielded best performing results.

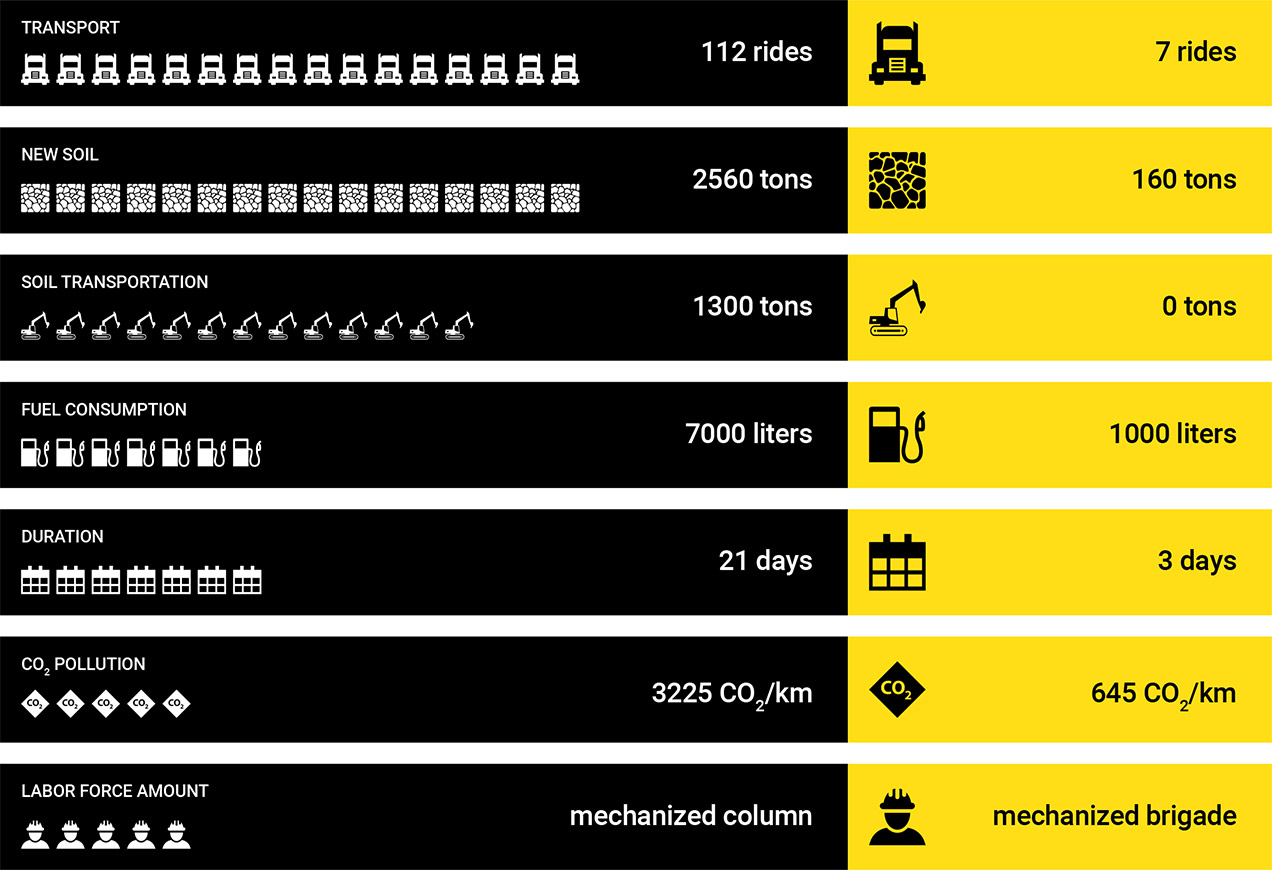

StabilRoad® provides an ecological advantage

StabilRoad® technology gives a very high ecological advantage over traditional road construction. As a result less energy is consumed, the amount of harmful exhaust gases to the surrounding environment is reduced due to the removal and reloading of filler surfaces. The negative public response resulting from the high-volume transport of huge inert materials will decrease and the use of non-renewable natural resources decreases too. While using StabilRoad® technology, it is very important to remember that all contaminated surfaces (including harmful substances, petroleum products) are dis-sectioned from the rest of the environment during stabilization. Therefore no contamination from the soil is released into the nature!

StabilRoad® Time and Construction

StabilRoad® saves you time and reduces costs

Recycling and re-use of local soils and materials provides

- Expenses related to excavation, exportation and utilization of soil are excluded or minimized

- There is little or no significant need for the purchase and transport of inert aggregates

- The thickness of superficial stabilizing layers is significantly reduced compared to classical stabilization

- The frost resistance of the superficial layers is significantly increased

- Significantly accelerates the construction process

- The stabilized surface is ready for traffic within in 4-6 hours after completion of the work